Extraordinary solutions for the future of dentistry.

What we do

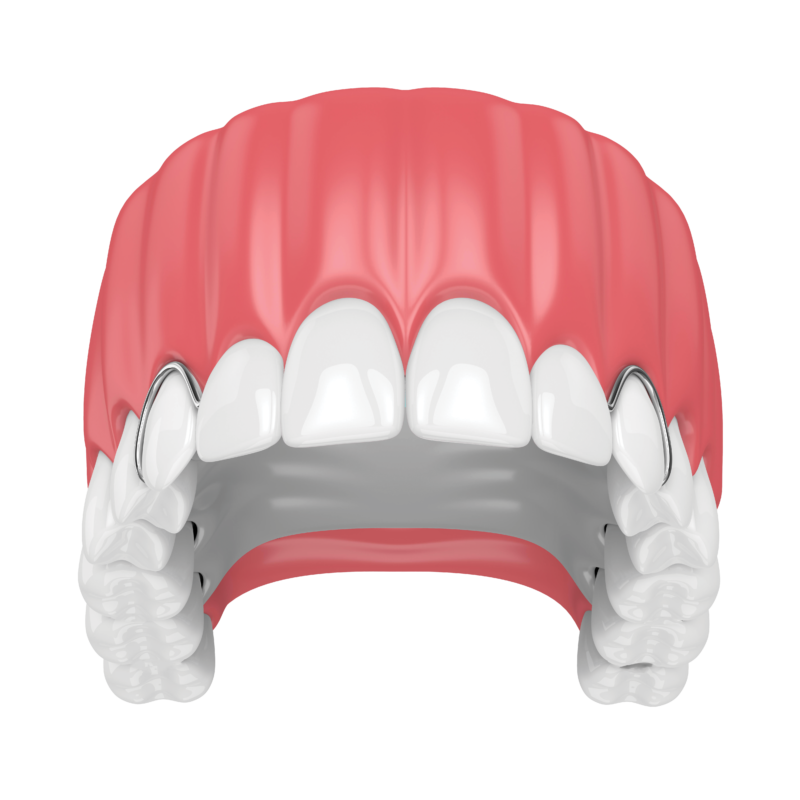

We put smiles on faces. It's what we do.

At Swift Dental, we create dental solutions that make you and your patients smile. Because for us, knowing you’re happy with our service, is the reason why we’re here.

Digital Future

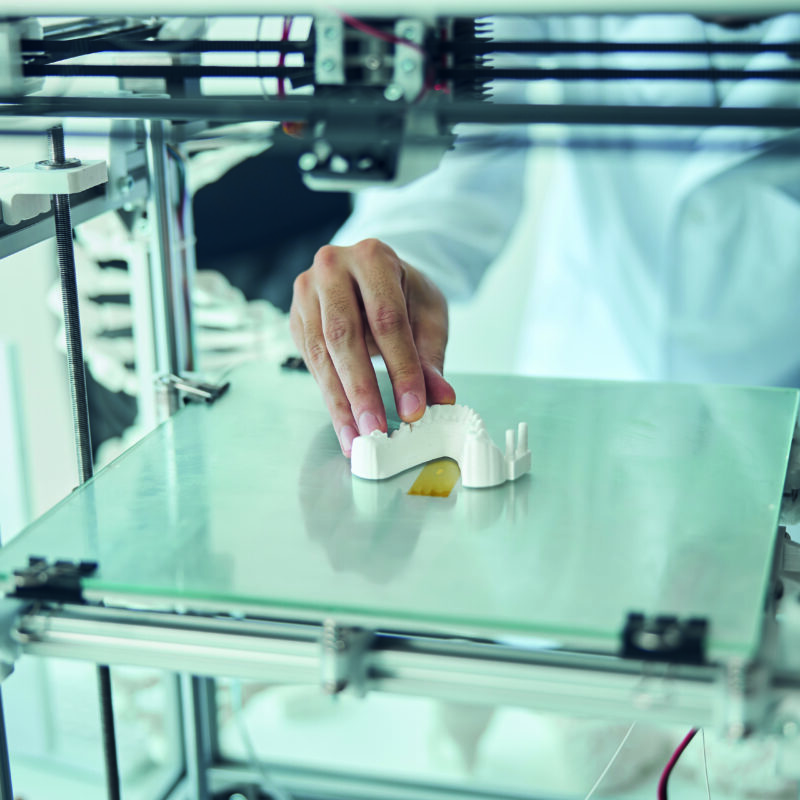

Fast-tracking a new digital future.

The smart technology and bespoke software housed at our custom-built headquarters in Bolton and ably supported by our nationwide network of logistics hubs, makes Swift Dental Group an ultra-reliable one-stop shop for all dental restorative work, wherever you are in the UK.

Plus we're due to expand into a brand new state-of-the art lab this July.

Solutions

Swift Solutions

We think forward about new ways to support you.

Get In Touch

To every customer, we aim to be a true dental partner. Get in touch today to find out how our dental solutions can help you.